We recently upgraded the truck from a ’15 Ram 3500 SRW pickup to a ’17 F-350 DRW flatbed. We did this for a couple of reasons. First, we were slightly over the gross RAWR for the RAM when fully loaded and we have ideas for additional “things” that would be nice to take along, but would put us further to the backside of the weight scale. Second, while the roads in our immediate area (within two days drive) are all in pretty good condition, we would like to venture to other parts of the country where, from experience, we know there are pot-holes that could swallow us alive, so the more rubber, springs and capacity we have the more comfortable we will be.

We found this truck at a local dealer, who was accommodating enough to let us test drive it to the house where we raised the camper, backed it under and made sure our parking lot measurements were actually going to work. Thankfully, they did and it fit without issue. This is a F-350 chassis cab (as Ford refers to it), with the 14k gvw option and a diamond plate flatbed with flush mount fifth wheel ball. The door sticker shows a gross FAWR of 5600 and gross RAWR of 10040. The dealer also let us spin through the local CAT scales where we discovered our empty steer axle weight is 5060 and drive axle weight of 4080.

The camper is sitting on a double layer stall mat which provides a cushion soft, non-skid/slip area as well as raises the camper 1.5″ which we wanted to do for roof/headache rack clearance as well as bed siderail clearance.

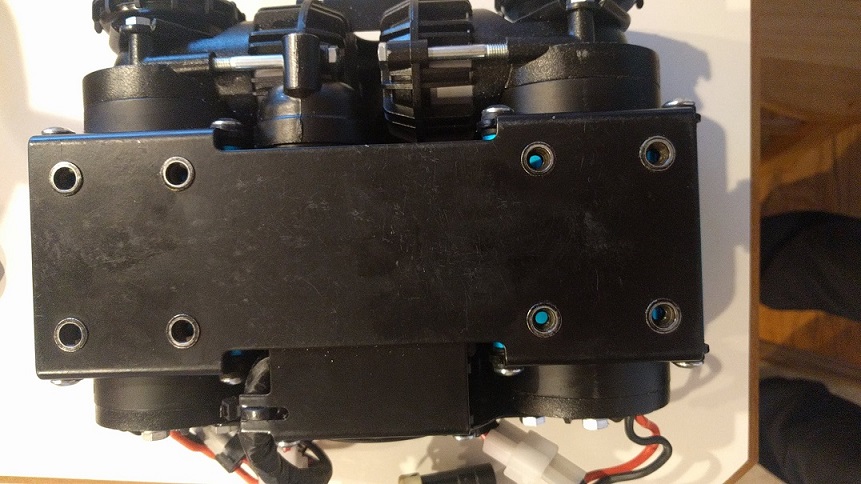

For tiedowns we are using our Torklift Fastguns from the RAM, but we cut off the threaded rod to allow for maximum shortening so we can fasten to flatbed deck. For the rears we installed two marine padeyes that are thru bolted with backing plates and for the fronts we drilled a 3/4″ hole in the flatbed gusset.

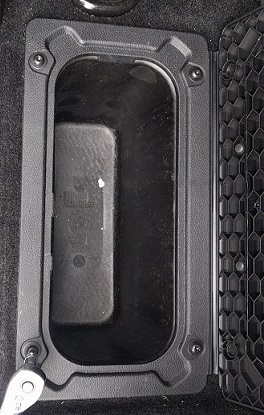

We also transferred our ARB air compressor from the RAM to a toolbox. It was nice to have this mounted in the cab of the RAM, but the Ford doesn’t offer the same in-floor storage so the toolbox was best option. A nice feature of the Ford is the upfitter switches. There are 6 toggle switches in the cieling of the cab all pre-wired to an easily accessible fuse box with wires in the engine compartment.

One thing we both miss about the RAM is the Cummins engine brake. While the Ford does have an active engine brake, it makes non of the ‘jake brake’ type noise when de-accelerating. Oh well. We did a maiden voyage with the new truck a couple weekends ago to the Asheville area of North Carolina. We took the back roads heading west which meant slow, switchback type driving with uphill grades that felt like we were gaining a truck length in altitude for every truck length of progress. Then heading east we took the interstate and tested out the ‘quiet’ jake brake. It all seemed to work as designed in that it kept us at a steady 45mph with no brake or accel required. We stayed at a couple of Harvest Hosts where one seemed to be having a Mercedes camper van rally that we were invading (there were two more to left of us in the pict below). Wonderful folks and great food.

All in all a marvelous inaugural trip for the new unit.